Top 5 Mistakes to Avoid When Setting Up Stage Trussing

Stage trussing forms the backbone of modern entertainment infrastructure, supporting everything from lighting rigs to massive video walls. The structural integrity of these systems depends on proper planning, quality materials, and precise installation techniques. Unlike static structures such as roof trusses or truss bridges, stage trussing must handle dynamic loads, frequent assembly and disassembly, and varying environmental conditions.

Modern stage trussing has evolved from simple timber trusses to sophisticated flat steel trusses and box truss designs that maximize structural efficiency while minimizing weight. Understanding the fundamental principles that govern everything from attic truss design to Burr arch truss bridge design helps professionals make informed decisions about load distribution, joint specifications, and overall system stability.

The key to successful stage trussing lies in recognizing that each installation presents unique challenges. Factors such as venue architecture, load requirements, and setup constraints must be carefully evaluated using detailed blueprints for truss construction and engineering calculations that account for both concentrated loads and distributed forces.

#Mistakes 01: Overloading Trusses: Understanding Load Ratings

The most critical mistake in stage trussing is exceeding load limits without proper structural analysis. Every truss system, whether utilizing box trusses, lattice trusses, or specialized arch trusses, has specific load ratings that must be strictly observed.

Dynamic load calculations are particularly crucial in stage environments where equipment vibrates, moves, or experiences sudden force changes. Unlike static applications such as flat roof trusses or hip roof trusses, stage trussing must account for:

- Moving lights and motorized equipment

- Wind loads from outdoor venues

- Resonance effects from sound systems

- Personnel loads during rigging operations

Professional engineers use comprehensive blueprints for truss construction that specify not only the load limit for each component but also how concentrated loads should be distributed throughout the structure. Heavy loads require careful analysis of truss joints and connection points, as failure typically occurs at these critical intersections rather than in the main structural members.

Box truss design has become increasingly popular for stage applications because it provides superior resistance to torsional forces while maintaining reasonable weight. However, even the most robust flat steel trusses can fail if overloaded or if loads are applied incorrectly.

#Mistakes 02: Ignoring the Latest Materials and Technologies

Modern stage trussing has advanced significantly beyond traditional timber trusses, yet many installations still rely on outdated approaches that compromise both safety and efficiency. Contemporary flat steel trusses utilize high-strength alloys and precision manufacturing techniques, which significantly enhance structural integrity while reducing weight.

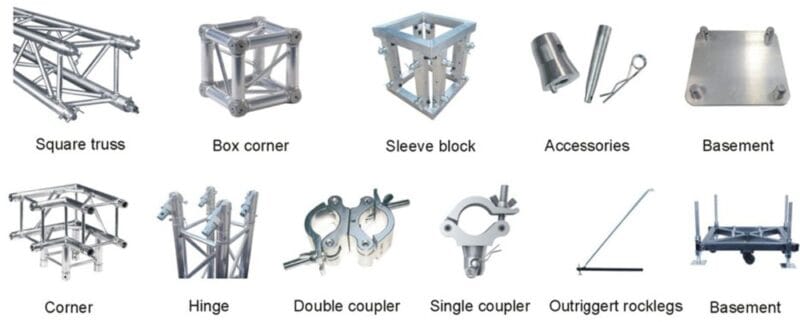

The box truss design represents one of the most significant advances in stage truss technology. These systems provide exceptional strength-to-weight ratios and superior resistance to both bending and torsional forces. Unlike traditional lattice trusses, box trusses distribute loads more evenly and provide better access for cable management and equipment mounting.

Advanced truss joints now utilize precision-engineered connections that eliminate many of the weak points found in older systems. Modern post-truss configurations can handle heavy loads while maintaining the flexibility required for complex stage designs. These improvements are particularly evident in applications requiring vaulted ceiling installations or complex truss patterns.

Material technology has also improved dramatically. High-strength steel enables the use of lighter flat steel trusses without compromising load capacity, while advanced coatings protect against corrosion and wear. Even when working with specialized applications, such as arch trusses or hip roof trusses for outdoor stages, modern materials provide superior performance and longevity.

The integration of intelligent monitoring systems into truss design allows real-time load monitoring and early warning of potential issues. This technology, combined with improved attic truss design principles borrowed from architectural applications, helps prevent failures before they occur.

#Mistakes 03:Neglecting Expert Consultation: The Importance of Professional Input

Professional consultation is essential for complex stage trussing projects, yet it’s often overlooked in budget-conscious installations. Structural engineers specializing in entertainment rigging understand the unique challenges of stage environments and can identify potential issues that might not be apparent to general contractors or inexperienced riggers.

Expert consultation becomes particularly critical when working with complex systems such as truss bridges spanning large distances or when integrating multiple truss patterns in a single installation. Professional engineers can optimize structural efficiency while ensuring all safety requirements are met.

The design process for stage trussing involves a detailed analysis of load paths, connection details, and potential failure modes. This is especially important when working with heavy loads or when employing innovative approaches, such as Burr arch truss bridge design, for long-span applications. Professional input ensures that all calculations account for dynamic load effects and properly specify diagonal bracing requirements.

Structural engineers also provide crucial input on foundation requirements and anchor point specifications. A strong foundation is essential for safe trussing operations, and professional analysis ensures that ground conditions, anchor capacities, and load transfer mechanisms are properly evaluated.

When working with specialized applications such as attic trusses for theatrical fly galleries or box trusses for complex lighting rigs, expert consultation helps optimize the design for both structural performance and operational efficiency. Professional engineers understand how different truss joints perform under various loading conditions and can specify the most appropriate connections for each application.

#Mistakes 04:Incorrect Rigging Practices: Securing with Precision

Rigging errors represent one of the most common causes of stage truss failures, often resulting from inadequate understanding of load transfer mechanisms and connection requirements. Proper rigging requires careful attention to every detail, from the installation of diagonal bracing to the specification of individual truss joints.

The installation of diagonal bracing is particularly critical, as these members provide essential stability against lateral forces and buckling. Many failures occur because riggers underestimate the importance of proper bracing installation or use inadequate connection details. Whether working with simple lattice trusses or complex box truss configurations, diagonal bracing must be installed according to engineering specifications.

Truss joints require special attention during installation, as these connections typically represent the weakest points in the system. Proper torque specifications, appropriate hardware selection, and correct installation sequences are essential for maintaining structural integrity. This is particularly important when working with heavy loads or when installing complex truss patterns that create unusual force distributions.

Connection details become even more critical when working with specialized systems such as arch trusses or when adapting designs originally intended for applications like flat roof trusses or hip roof trusses. Each connection must be properly analyzed and installed to ensure adequate load transfer capacity.

The rigging of flat steel trusses requires particular care in managing both vertical loads and lateral forces. Improper installation can create concentrated loads that exceed the capacity of individual members or connections, resulting in the progressive failure of the entire system.

#Mistakes 05:Omitting Safety Measures: The Role of Safety Cables in Rigging

Safety cable installation represents the final line of defense against catastrophic failure, yet it’s often treated as an afterthought rather than an integral part of the trussing system. Proper safety cable installation requires an understanding of load paths, failure modes, and redundancy requirements.

Safety cables must be sized and positioned to handle the full load of any equipment or structural component they protect. This requires careful analysis of potential failure scenarios and proper specification of cable capacities, attachment points, and load distribution mechanisms. Whether working with simple post-truss configurations or complex box-truss assemblies, safety cables provide essential backup protection.

The installation of safety cables becomes particularly critical when working with systems that experience dynamic loads or when equipment is suspended at significant heights. Safety cable routing must avoid interference with normal operations while providing adequate protection in failure scenarios.

Special attention must be paid to safety cable attachment points, as these connections must be capable of handling sudden shock loads that occur during failure events. This is particularly important when working with heavy loads or when using safety cables to protect entire sections of trussing.

Safety cable installation also requires consideration of cable management and maintenance requirements. Cables must be easily inspectable and replaceable, and installation details must prevent damage from regular operations or environmental factors.

Conclusion: Ensuring Stability and Effectiveness Through Best Practices

Successful stage trussing requires careful attention to engineering principles, proper material selection, expert consultation, precise installation practices, and comprehensive safety measures. Whether working with traditional timber trusses or modern flat steel trusses, the fundamental principles of structural integrity remain constant.

The evolution from simple lattice trusses to sophisticated box truss designs reflects the industry’s commitment to improving both safety and performance. Modern stage trussing systems provide exceptional structural efficiency while meeting the demanding requirements of contemporary entertainment productions.

By avoiding the five critical mistakes outlined above—overloading, ignoring modern technologies, neglecting expert consultation, incorrect rigging practices, and omitting safety measures—professionals can ensure that their stage trussing installations provide reliable, safe, and efficient support for even the most demanding applications.

The key to success lies in understanding that stage trussing represents a complex engineered system where every component, from individual truss joints to overall truss patterns, plays a critical role in maintaining structural integrity. Through proper planning, quality materials, expert guidance, and meticulous installation practices, stage trussing can provide the strong foundation necessary for spectacular and safe entertainment experiences.